When it comes to maintaining your Toyota vehicle, selecting the right Toyota Parts is crucial for ensuring optimal performance, longevity, and reliability. Toyota has built a reputation for manufacturing vehicles that stand the test of time, but even the most well-engineered automobiles require proper maintenance and genuine components to continue operating at peak efficiency. Understanding the importance of authentic Toyota Parts and knowing where to source them can make the difference between a vehicle that serves you reliably for decades and one that experiences premature wear and costly repairs.

Understanding Toyota's Engineering Excellence

Manufacturing Standards and Quality Control

Toyota's commitment to quality extends far beyond the initial vehicle assembly process into every component and replacement part manufactured under the Toyota brand. The company employs stringent quality control measures that ensure each part meets the exact specifications and tolerances required for optimal vehicle performance. These manufacturing standards are developed through decades of research, testing, and continuous improvement processes that have established Toyota as a leader in automotive reliability and durability.

The quality control process begins with material selection, where Toyota engineers specify precise metallurgical compositions, polymer formulations, and manufacturing processes that guarantee consistent performance across various operating conditions. Each component undergoes rigorous testing protocols that simulate real-world usage scenarios, extreme weather conditions, and extended service intervals to ensure that genuine Toyota Parts deliver the performance characteristics drivers expect from their vehicles.

Research and Development Investment

Toyota invests billions of dollars annually in research and development to continuously improve their parts and components, ensuring that each generation of replacement parts incorporates the latest technological advances and engineering improvements. This investment translates into parts that not only meet current performance standards but often exceed the specifications of the original components installed during vehicle manufacturing.

The company's global network of research facilities works collaboratively to develop innovative solutions that address common wear patterns, environmental challenges, and performance optimization opportunities. This collaborative approach ensures that Toyota Parts benefit from the collective expertise of engineers worldwide, resulting in components that deliver superior performance regardless of geographic location or operating conditions.

Engine Components and Performance Systems

Oil and Fluid Systems

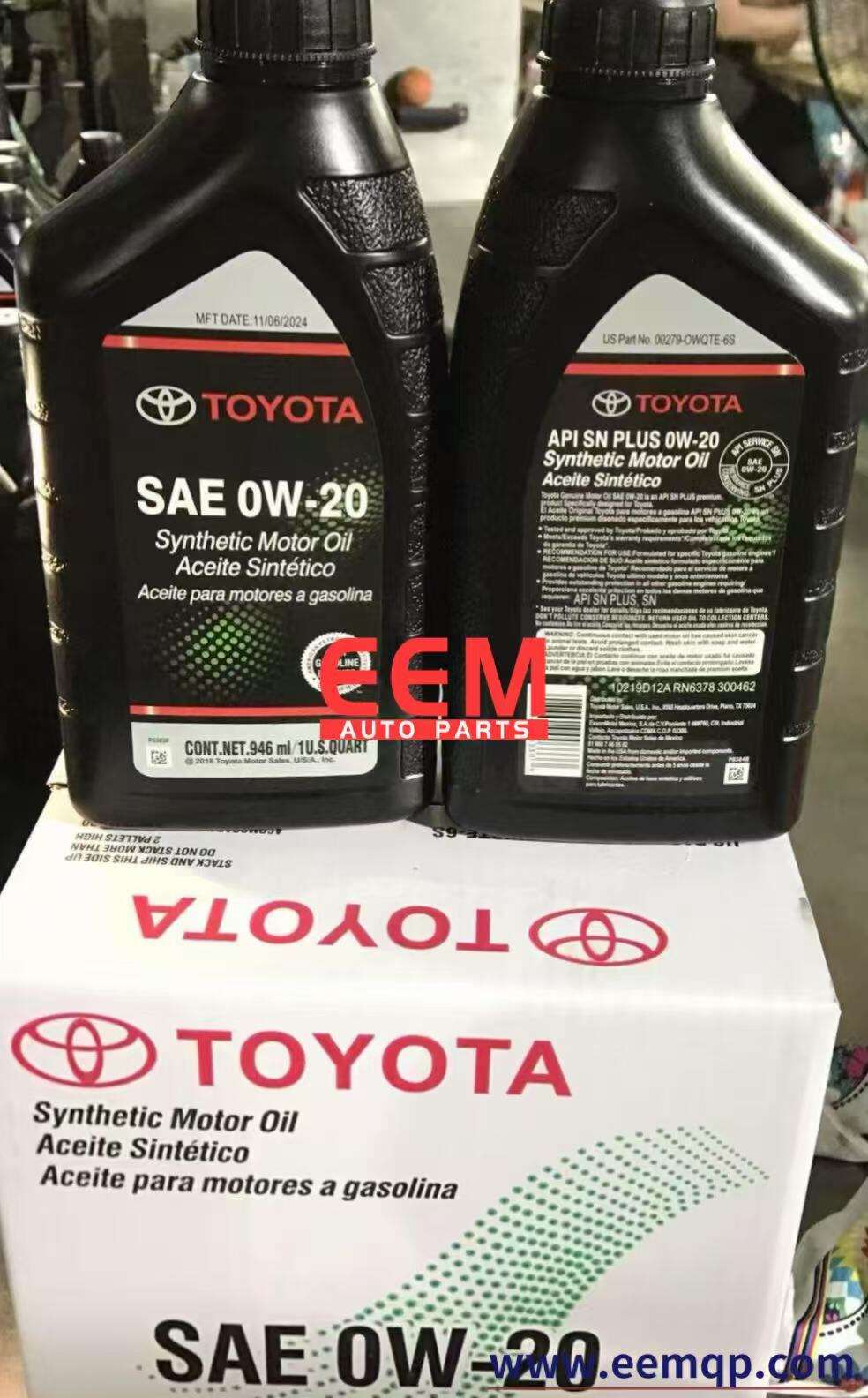

One of the most critical aspects of Toyota vehicle maintenance involves the selection and regular replacement of engine oils and fluids specifically formulated for Toyota engines. Toyota Parts include specially formulated lubricants that provide optimal protection for the precise tolerances and advanced metallurgy found in modern Toyota engines, ensuring maximum performance and longevity.

These specialized fluids are developed through extensive collaboration between Toyota engineers and leading petroleum companies to create formulations that address the specific requirements of Toyota's advanced engine technologies. The result is a complete line of lubricants and fluids that provide superior protection against wear, deposits, and thermal breakdown while maintaining optimal viscosity characteristics across a wide range of operating temperatures.

Air and Fuel System Components

Toyota's air and fuel system components are engineered to work in perfect harmony with the vehicle's engine management systems, ensuring optimal fuel economy, emissions performance, and power delivery. These components include air filters, fuel filters, fuel injectors, and throttle body assemblies that are calibrated to meet the precise flow characteristics required by each specific engine configuration.

The precision manufacturing processes used to create these components ensure that each part maintains the exact dimensional tolerances required for proper fit and function. This attention to detail is particularly important in modern Toyota vehicles that employ advanced engine management systems capable of detecting even minor variations in component performance and adjusting engine parameters accordingly.

Suspension and Steering Systems

Shock Absorbers and Struts

Toyota's suspension system components are designed to provide the perfect balance between ride comfort, handling precision, and long-term durability that Toyota owners expect from their vehicles. Genuine shock absorbers and struts incorporate advanced valve technologies and specialized fluid formulations that maintain consistent damping characteristics throughout their service life, ensuring that the vehicle's handling and ride quality remain unchanged over time.

The engineering team responsible for developing these components works closely with Toyota's vehicle dynamics specialists to ensure that each shock absorber and strut assembly contributes to the overall driving experience that defines each Toyota model. This collaborative approach results in suspension components that not only provide excellent performance but also integrate seamlessly with other vehicle systems such as electronic stability control and anti-lock braking systems.

Steering Components and Alignment

Toyota's steering system components are manufactured to precise specifications that ensure accurate steering response, minimal play, and long service life under various driving conditions. These components include tie rods, ball joints, steering racks, and power steering pumps that work together to provide the responsive and predictable steering characteristics that Toyota drivers appreciate.

The precision manufacturing processes used to create steering components ensure that proper wheel alignment can be maintained throughout the component's service life, contributing to even tire wear patterns and optimal fuel economy. This attention to dimensional accuracy also helps maintain the vehicle's original handling characteristics and ensures that safety systems dependent on precise steering input continue to function as designed.

Braking System Excellence

Brake Pads and Rotors

Toyota's braking system components are developed using advanced materials science and extensive testing protocols to ensure consistent stopping power, minimal noise, and long service life. Genuine brake pads incorporate friction materials specifically formulated to work optimally with Toyota's brake rotor designs, providing smooth and predictable braking performance across a wide range of operating conditions.

The development process for brake components includes extensive dynamometer testing and real-world driving evaluations to ensure that each component meets Toyota's stringent performance and durability standards. This comprehensive testing approach ensures that genuine Toyota Parts provide the reliable braking performance that drivers depend on for safety and confidence in all driving situations.

Brake Fluid and Hydraulic Components

Toyota's brake fluid and hydraulic system components are engineered to provide consistent performance and long-term reliability in the demanding environment of modern brake systems. These components include brake master cylinders, brake calipers, and specialized brake fluid formulations that maintain optimal performance characteristics even under extreme temperature conditions and extended service intervals.

The hydraulic components used in Toyota braking systems are manufactured using advanced materials and precision machining processes that ensure consistent performance and minimal maintenance requirements. These components are designed to work seamlessly with Toyota's electronic brake-force distribution systems and other advanced safety technologies to provide optimal braking performance in all driving conditions.

Electrical and Electronic Systems

Battery and Charging Systems

Toyota's electrical system components are designed to meet the increasing power demands of modern vehicles while providing long-term reliability and consistent performance. Genuine batteries, alternators, and starter motors incorporate advanced technologies that ensure reliable operation even under extreme weather conditions and demanding electrical loads from modern automotive electronics.

The development of electrical system components involves extensive collaboration with leading technology suppliers to ensure that each component incorporates the latest advances in materials science and electronic design. This collaborative approach results in electrical components that provide superior performance while maintaining the reliability and durability that Toyota owners expect.

Sensors and Control Modules

Modern Toyota vehicles rely on an extensive network of sensors and electronic control modules to optimize engine performance, emissions control, and safety system operation. These electronic components are manufactured to precise specifications and undergo rigorous quality control testing to ensure accurate operation throughout their service life.

The precision required in manufacturing these electronic components demands sophisticated production facilities and advanced testing equipment that can verify proper operation under all operating conditions. Toyota's investment in these manufacturing capabilities ensures that replacement electronic components provide the same level of accuracy and reliability as the original equipment installed during vehicle production.

Maintenance Scheduling and Service Intervals

Preventive Maintenance Programs

Toyota's comprehensive maintenance scheduling system is designed to maximize vehicle reliability and longevity while minimizing total ownership costs through strategic component replacement intervals. These maintenance schedules are developed based on extensive real-world testing and statistical analysis of component failure patterns to ensure that parts are replaced before they reach the end of their useful service life.

The preventive maintenance approach employed by Toyota takes into account various factors including driving conditions, climate, and vehicle usage patterns to provide customized maintenance recommendations that optimize both vehicle performance and cost-effectiveness. This data-driven approach ensures that Toyota Parts are replaced at intervals that maximize their value while maintaining optimal vehicle performance and reliability.

Service Documentation and Tracking

Proper documentation of maintenance activities and parts replacement is essential for maintaining vehicle warranty coverage and ensuring that future maintenance activities are performed at appropriate intervals. Toyota's service documentation systems provide comprehensive tracking of all maintenance activities and parts installations, creating a detailed service history that can be valuable for both current ownership and future resale considerations.

The documentation system also provides service technicians with access to complete vehicle history information, enabling them to make informed decisions about maintenance recommendations and identify potential issues before they become costly problems. This proactive approach to vehicle maintenance helps ensure that Toyota vehicles continue to provide reliable service throughout their operational life.

FAQ

What makes genuine Toyota parts different from aftermarket alternatives

Genuine Toyota parts are manufactured to the exact specifications and quality standards established during the original vehicle development process, ensuring perfect fit, optimal performance, and long-term reliability. These parts undergo extensive testing and quality control procedures that may not be required for aftermarket alternatives, resulting in components that maintain the original vehicle characteristics and performance that Toyota owners expect.

How often should I replace Toyota parts during routine maintenance

Toyota provides specific maintenance schedules for each vehicle model and component type based on extensive testing and real-world performance data. Following these recommended service intervals ensures optimal vehicle performance and helps prevent unexpected failures. The maintenance schedule may vary based on driving conditions, climate, and vehicle usage patterns, so consulting your owner's manual or Toyota service advisor is recommended for personalized maintenance recommendations.

Can using non-genuine parts affect my Toyota's warranty coverage

While warranty coverage cannot be denied solely based on the use of non-genuine parts, any vehicle damage or failure directly attributable to the use of non-genuine parts may not be covered under warranty. Using genuine Toyota parts ensures that warranty coverage is maintained and provides peace of mind that replacement components meet Toyota's quality and performance standards.

Where can I find reliable sources for genuine Toyota parts

Genuine Toyota parts are available through authorized Toyota dealerships, certified parts distributors, and reputable online retailers that specialize in authentic automotive components. When purchasing parts online, verify that the supplier is authorized to sell genuine Toyota products and check that part numbers match your vehicle's specifications to ensure proper fit and function.