China has emerged as a dominant force in the global automotive lubricant manufacturing sector, with numerous specialized facilities producing high-quality engine oils, transmission fluids, and specialized lubricants for the international market. The country's automotive lubricant factory infrastructure represents a sophisticated blend of advanced technology, stringent quality control, and cost-effective production capabilities that serve both domestic and export markets. Modern Chinese manufacturing facilities have invested heavily in state-of-the-art blending equipment, automated packaging systems, and comprehensive testing laboratories to ensure their products meet international standards including API, ACEA, and OEM specifications.

The competitive landscape of Chinese lubricant manufacturing has evolved significantly over the past decade, with many facilities achieving ISO 9001, ISO 14001, and OHSAS 18001 certifications to demonstrate their commitment to quality, environmental responsibility, and workplace safety. These manufacturing plants typically feature multiple production lines capable of handling various viscosity grades, from conventional mineral oils to fully synthetic formulations designed for modern high-performance engines.

Manufacturing Infrastructure and Capabilities

Production Facility Design and Layout

A typical automotive lubricant factory in China incorporates a carefully planned layout that optimizes workflow efficiency while maintaining strict quality control standards. The facility design usually includes separate areas for raw material storage, blending operations, quality testing, packaging, and finished goods warehousing. Modern plants feature temperature-controlled environments to ensure consistent product quality throughout the manufacturing process. The production areas are designed with easy-to-clean surfaces, proper ventilation systems, and contamination prevention measures to maintain the highest standards of product purity.

Storage tanks for base oils and additives are strategically positioned to minimize handling and transfer distances while ensuring proper segregation of different product categories. Many facilities utilize overhead piping systems with automated valves to reduce the risk of cross-contamination and improve operational efficiency. The packaging area typically features multiple filling lines capable of handling various container sizes, from small bottles to large drums and intermediate bulk containers.

Quality Control and Testing Capabilities

Contemporary Chinese lubricant manufacturing facilities maintain comprehensive in-house laboratories equipped with sophisticated testing equipment to verify product specifications at every stage of production. These laboratories typically include viscosity analyzers, flash point testers, pour point apparatus, and oxidation stability equipment to ensure each batch meets or exceeds specified requirements. Advanced spectroscopic equipment allows for detailed analysis of additive packages and contamination detection.

The quality assurance process begins with incoming raw material inspection and continues through blending verification, intermediate testing, and final product certification. Many facilities maintain statistical process control systems that monitor key parameters continuously, enabling immediate corrective action when deviations occur. This systematic approach to quality management ensures consistent product performance and helps maintain customer confidence in the manufactured lubricants.

Product Range and Specialization

Engine Oil Manufacturing

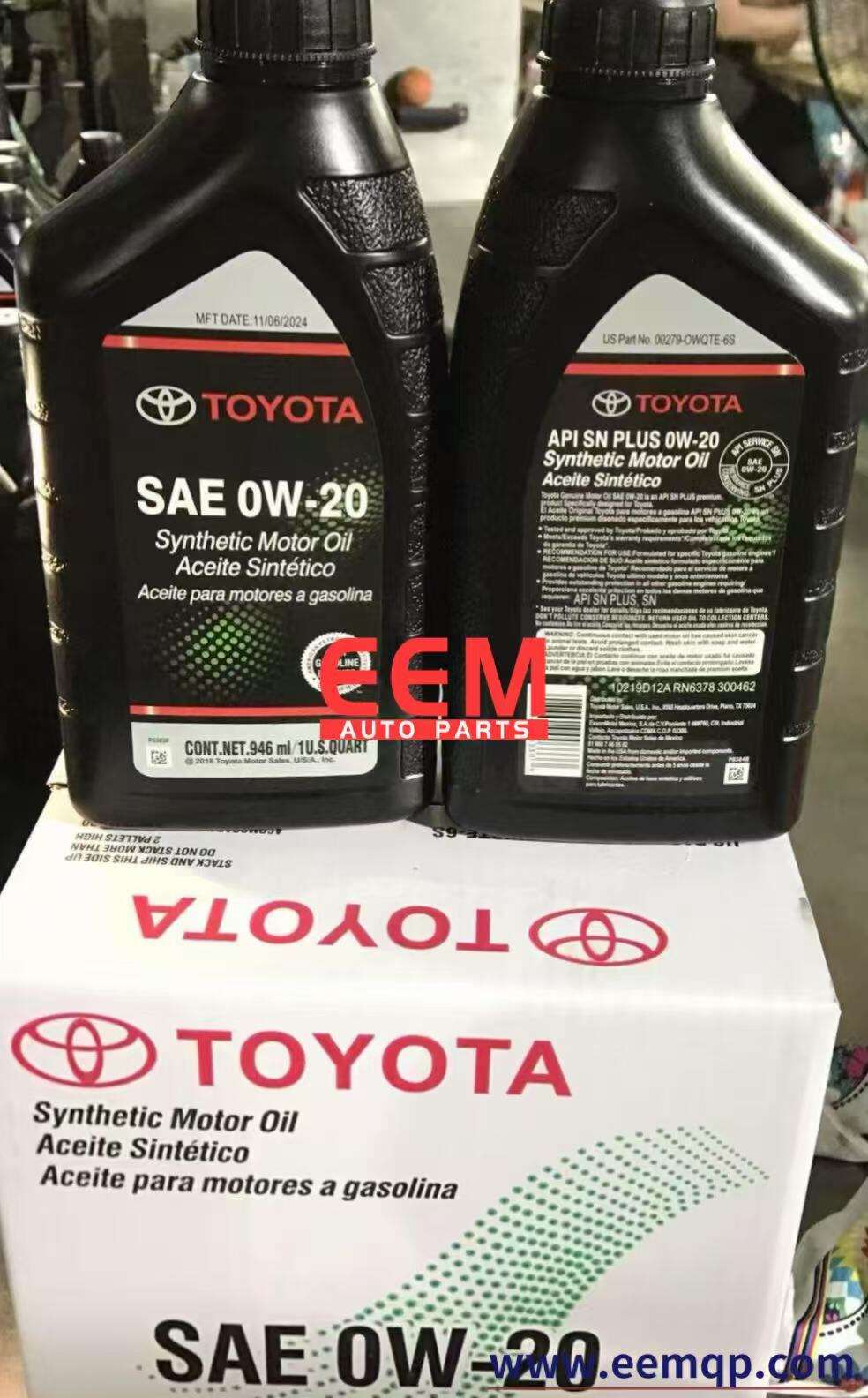

Engine oil production represents the core competency of most automotive lubricant factories in China, encompassing a wide range of viscosity grades and performance levels. Manufacturing facilities typically produce conventional, semi-synthetic, and fully synthetic engine oils designed to meet various API service categories including SN, SP, and the latest SN Plus specifications. The production process involves precise blending of base oils with carefully selected additive packages to achieve specific performance characteristics such as wear protection, oxidation resistance, and thermal stability.

Many Chinese manufacturers have developed expertise in producing OEM-approved formulations for major automotive brands, requiring strict adherence to proprietary specifications and testing protocols. This capability has positioned several facilities as preferred suppliers for international automotive companies seeking cost-effective manufacturing solutions without compromising quality standards. The flexibility to produce both high-volume standard grades and specialized low-volume formulations makes these facilities attractive partners for diverse market segments.

Transmission Fluid and Gear Oil Production

Beyond engine oils, modern Chinese lubricant manufacturing facilities have expanded their capabilities to include automatic transmission fluids, manual transmission oils, and differential gear lubricants. These specialized products require different base oil selections and additive technologies compared to engine oils, demanding additional technical expertise and production flexibility. The manufacturing process for transmission fluids involves careful control of friction characteristics, oxidation stability, and seal compatibility to ensure proper transmission operation across various operating conditions.

Gear oil production requires particular attention to extreme pressure additives and viscosity characteristics at low temperatures, as these products must provide reliable protection under severe operating conditions. Many facilities maintain separate production lines for gear oils to prevent cross-contamination with engine oil additives that could compromise gear oil performance. The ability to produce both conventional and synthetic gear oils expands the market reach and application versatility of these manufacturing operations.

Technology and Innovation

Advanced Blending Systems

Modern automotive lubricant factory operations in China utilize computer-controlled blending systems that ensure precise additive dosing and homogeneous mixing of all components. These systems feature automated recipe management, real-time monitoring of blend composition, and integrated quality control checkpoints that verify specification compliance before product release. The blending equipment typically includes high-efficiency mixers capable of handling various batch sizes while maintaining consistent mixing energy and temperature control.

Advanced facilities incorporate inline monitoring systems that continuously analyze key parameters such as viscosity, density, and additive concentration during the blending process. This real-time feedback enables immediate adjustments to maintain target specifications and reduces the likelihood of off-specification batches that require reprocessing. The integration of statistical process control with blending operations helps optimize production efficiency while minimizing raw material waste and energy consumption.

Environmental and Safety Technologies

Environmental stewardship has become increasingly important for Chinese lubricant manufacturers, with many facilities implementing advanced technologies to minimize their environmental impact. Vapor recovery systems capture and process solvent emissions from production operations, while wastewater treatment systems ensure that process water meets discharge standards before release. Energy-efficient heating and cooling systems reduce overall energy consumption, and many facilities have incorporated renewable energy sources such as solar panels to offset electrical consumption.

Safety technologies include automated fire suppression systems, gas detection equipment, and emergency shutdown systems that protect personnel and equipment in the event of process upsets. Advanced process control systems monitor critical safety parameters continuously and initiate protective actions when predetermined limits are exceeded. These safety measures not only protect workers and facilities but also help maintain production continuity and product quality.

Market Position and Global Reach

Export Market Development

Chinese automotive lubricant manufacturers have successfully penetrated international markets by combining competitive pricing with reliable quality and flexible manufacturing capabilities. Many facilities have obtained international certifications and approvals that enable them to supply products to demanding markets in Europe, North America, and other regions with strict regulatory requirements. The development of long-term partnerships with international distributors and OEM customers has provided stable revenue streams and growth opportunities.

Export success has been supported by investments in logistics infrastructure, including strategically located distribution centers and partnerships with international shipping companies. Many manufacturers have developed specialized packaging and labeling capabilities to meet diverse regional requirements, while maintaining efficient inventory management systems that ensure product availability and freshness. The ability to provide technical support and product documentation in multiple languages has further enhanced their competitive position in global markets.

Domestic Market Leadership

Within China's rapidly expanding automotive market, domestic lubricant manufacturers have established strong positions by offering products specifically formulated for local driving conditions and vehicle populations. The growing preference for higher-quality lubricants among Chinese consumers has created opportunities for premium product lines and value-added services. Many facilities have developed strong relationships with local automotive service chains, parts distributors, and fleet operators who require reliable lubricant supplies and technical support.

The domestic market success has been built on understanding local customer needs, competitive pricing strategies, and comprehensive distribution networks that ensure product availability across diverse geographic regions. Technical support capabilities, including field service and application assistance, have helped differentiate these manufacturers from international competitors while building customer loyalty and market share.

FAQ

What certifications should I look for when selecting an automotive lubricant factory in China

When evaluating Chinese automotive lubricant manufacturers, look for ISO 9001 quality management certification, ISO 14001 environmental management certification, and relevant API or ACEA product approvals. Additional certifications to consider include OHSAS 18001 for occupational health and safety, and specific OEM approvals if you require products for particular vehicle brands. These certifications demonstrate the manufacturer's commitment to quality, environmental responsibility, and operational excellence.

How do Chinese automotive lubricant factories ensure product quality consistency

Reputable Chinese lubricant manufacturers maintain product quality consistency through comprehensive quality management systems that include incoming raw material inspection, in-process monitoring, and finished product testing. They utilize statistical process control methods, maintain calibrated testing equipment, and implement batch tracking systems that ensure traceability throughout the production process. Regular third-party audits and continuous improvement programs help maintain high quality standards over time.

What is the typical lead time for custom lubricant formulations from Chinese manufacturers

Lead times for custom lubricant formulations vary depending on the complexity of the specification and required testing protocols, but typically range from 4-8 weeks for initial development and approval. Production lead times for approved formulations generally range from 2-4 weeks depending on order quantity and production scheduling. Manufacturers with established R&D capabilities and flexible production systems can often accommodate rush orders or provide expedited development services for critical applications.

Can Chinese automotive lubricant factories provide private label packaging services

Most established Chinese automotive lubricant manufacturers offer comprehensive private label services including custom packaging design, multi-language labeling, and various container options from small bottles to bulk containers. They typically maintain flexible packaging lines that can accommodate different bottle shapes, label designs, and closure types while meeting regional regulatory requirements. Many facilities also provide value-added services such as shrink wrapping, case packing, and palletization to support customer distribution requirements.

Table of Contents

- Manufacturing Infrastructure and Capabilities

- Product Range and Specialization

- Technology and Innovation

- Market Position and Global Reach

-

FAQ

- What certifications should I look for when selecting an automotive lubricant factory in China

- How do Chinese automotive lubricant factories ensure product quality consistency

- What is the typical lead time for custom lubricant formulations from Chinese manufacturers

- Can Chinese automotive lubricant factories provide private label packaging services